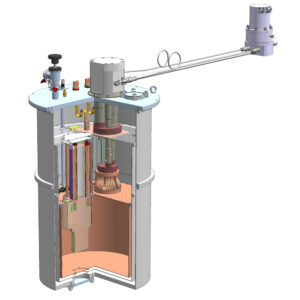

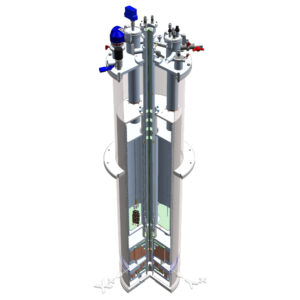

Scientific Magnetics specialise in the design and manufacture of a broad range of bespoke superconducting magnet systems

During the magnet specification and design phase, we consider the following technical areas.

Magnet Cooling

There are potentially three different commercially viable ways to cool a superconducting magnet:

Cryogen-free

Cryogen-free

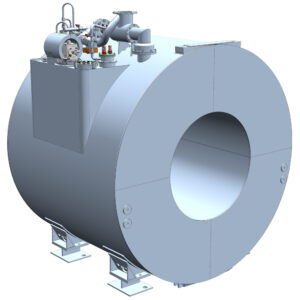

We estimate 90% of systems we manufacture today are Cryogen-free, utilising a 4K mechanical cryocooler. These cryocoolers are available in a variety of capacities, depending on the size of the system.

Using a mechanical cooler avoids the use of expensive liquid cryogens and can be easier for the end-user to site and minimises operator training.

Liquid Helium Bath

Liquid Helium Bath

Traditionally, superconducting magnets have been cooled using liquid helium. A liquid at atmospheric pressure, helium provides a very stable 4.2K environment.

The good thermal conduction between the liquid and the magnet allows faster ramping due to the cryogenically stable environment. In addition, there is the advantage that there is no motorised mechanical component, so there is a much lower level of vibration associated with this method of cooling.

Disadvantages though include the necessity to fill up the system with liquid cryogens at regular intervals and operate the system in a location designed to manage the potential release of cold gases in case of a loss of vacuum or magnet quench.

Recondensing

Recondensing

It is possible to combine the above methods to create a re-condensing liquid cryogen system. The magnet is cooled using liquid cryogens, but then the boiling liquid is re-cooled and condensed using a mechanical cryocooler. These hybrid systems can be suitable in installations where the cost of replacing the liquid helium is prohibitively high.

Typically, these hybrid systems have lower vibration levels than entirely cryogen-free magnets but cost more to manufacture as they require both a liquid cryogen vessel and the cryocooler. We offer many magnet designs for both wet and dry operation using high-performance materials to minimise weight and maximise available space for experimental requirements.

Where possible, we will provide standard magnets capable of operating in both wet and dry environments, enabling a more cost-effective testing process without the need for expensive cryogens.

Magnetic field strength

Two traditional superconductors can be used to create strong magnetic fields economically. At lower fields of up to 9 Tesla (T), niobium-titanium (NbTi) is the preferred superconducting material. Wires are created with a mixture of superconductors (divided into filaments) and copper, acting as thermal and electrical stabilisers.

At higher fields above 9T, Scientific Magnetics uses niobium-tin (Nb3Sn) as a superconductor with a much higher critical magnetic field. We currently offer magnets up to 12 T, although development work up to 14T is ongoing. Niobium Tin conductor is wound in a non-reacted state and must then undergo a heat treatment cycle in a vacuum furnace for several days. The process is managed on-site at our facility.

Vibration

Experimental customer requirements determine vibration specifications. Various system configurations are possible with a focus on reduced vibration. However, the cost tends to increase as the vibration levels decrease and other disadvantages must be considered.

GM cryocooler: Generally, this offers the most economical solution and is the simplest to implement. Isolating components are used where possible to reduce the vibration from the tip of the cold stage.

Pulse tube cryocooler: Very similar to the GM option with lower vibration levels due to the lack of cold displacer. However, the orientation of this cooler is very limited.

Gas-gap cryocooler: In this option, the cryocooler is decoupled from the rest of the system using a helium gas-gap. Thus, vibration levels are minimal. However, there is added complexity due to a second support structure required for the cryocooler.

Liquid cryogen: The lowest possible vibration levels can be achieved in both helium and nitrogen cooling systems. However, users require a higher level of operator training and the ongoing running costs are significantly higher.

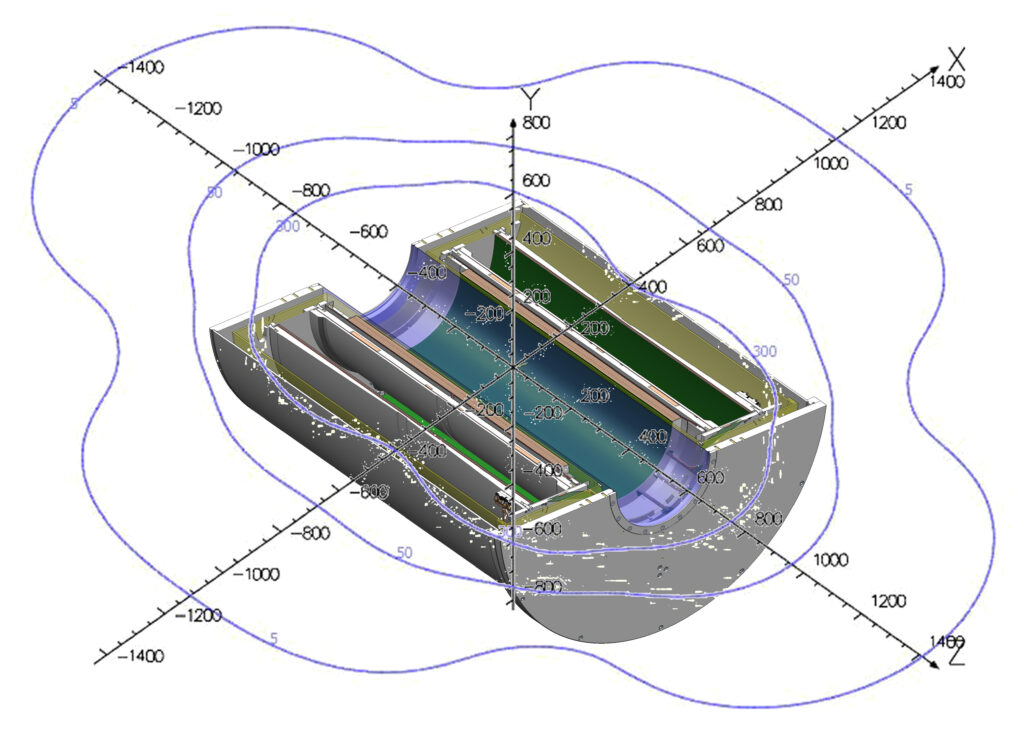

Active magnetic shielding

In certain situations, it is necessary to restrict the fringe field of the magnet system. This can be achieved in two ways. Passive shielding can be achieved by adding large ferromagnetic plates (generally mild steel) around the magnet. With careful design, the steel confines the magnetic field lines to the plates.

With active shielding, secondary coils are wound with a negative current, which cancels the fringe field. This option enables a more compact system and has the advantage of the shielding being completely linear with an energisation level. Scientific Magnetics offers both types of magnet systems.

Low Remnant Field Magnet Design

For some end-users, experimental protocol requires the magnetic field to be swept up to a maximum field and then back to exactly zero fields.

Scientific Magnetics offers a range of magnets where the remnant field (the magnetic field) left over when the current in the magnet returns to zero is minimised. This is done by geometry where possible and otherwise with careful wire selection.

For certain magnet systems, a very low current operation, or a particularly high inductance is required. Scientific Magnetics has many years of experience in low current magnet designs using very fine wires.

UHV

In specific experiments, the vacuum surrounding the magnet must be of particularly good quality. Ultra-high vacuum (UHV) is a range of vacuum typically better than 5.0×10-9 mbar and can be suitable for X-ray beamlines or scanning tunnelling microscopes.

Scientific Magnetics has many years of experience in manufacturing magnets, and current leads ideal for operation in UHV environments, where the choice of materials is critical to ensure minimal outgassing.

High homogeneity

Homogeneity or the uniformity of the magnetic field is a requirement for most systems to ensure that the field delivered by the magnet is the same across the entire sample. Different levels of uniformity are required and can be achieved. Generally, a simple split pair will have homogeneity levels of 1% over a region of a few millimetres.

To improve the uniformity, it is preferable to use solenoid magnets, which will tend to have a better homogeneity of 0.1%. Further improvements can be made by adding compensation coils to the solenoid, which can bring the level of uniformity to the 0.01% range.

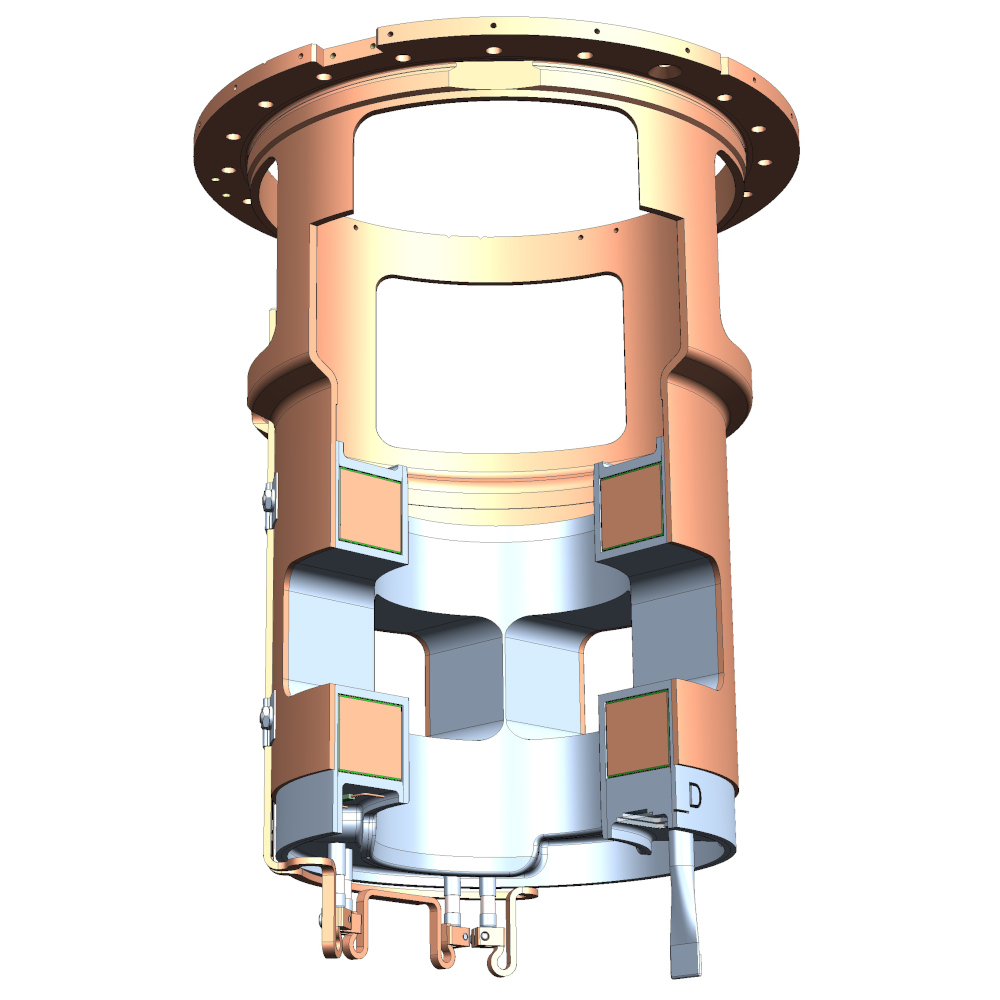

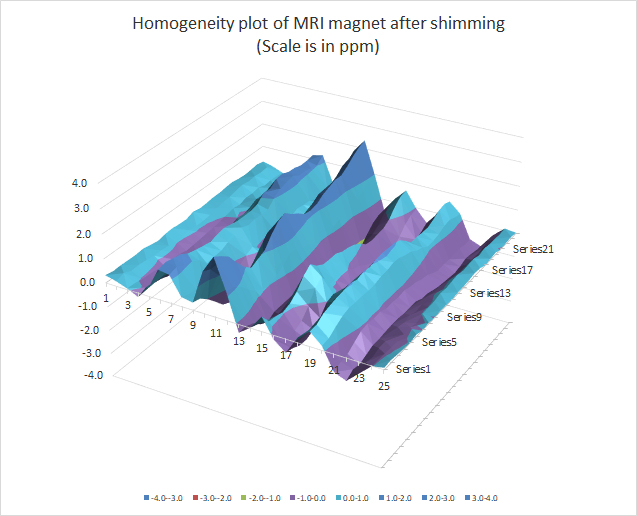

Scientific Magnetics also manufactures MRI magnets which have uniformity on the 1 part-per-million (ppm) range. These magnets use passive iron shims to correct for the inhomogeneity due to manufacturing tolerances. Accurate plotting with an NMR probe and an iterative process is used to converge to an optimal solution.

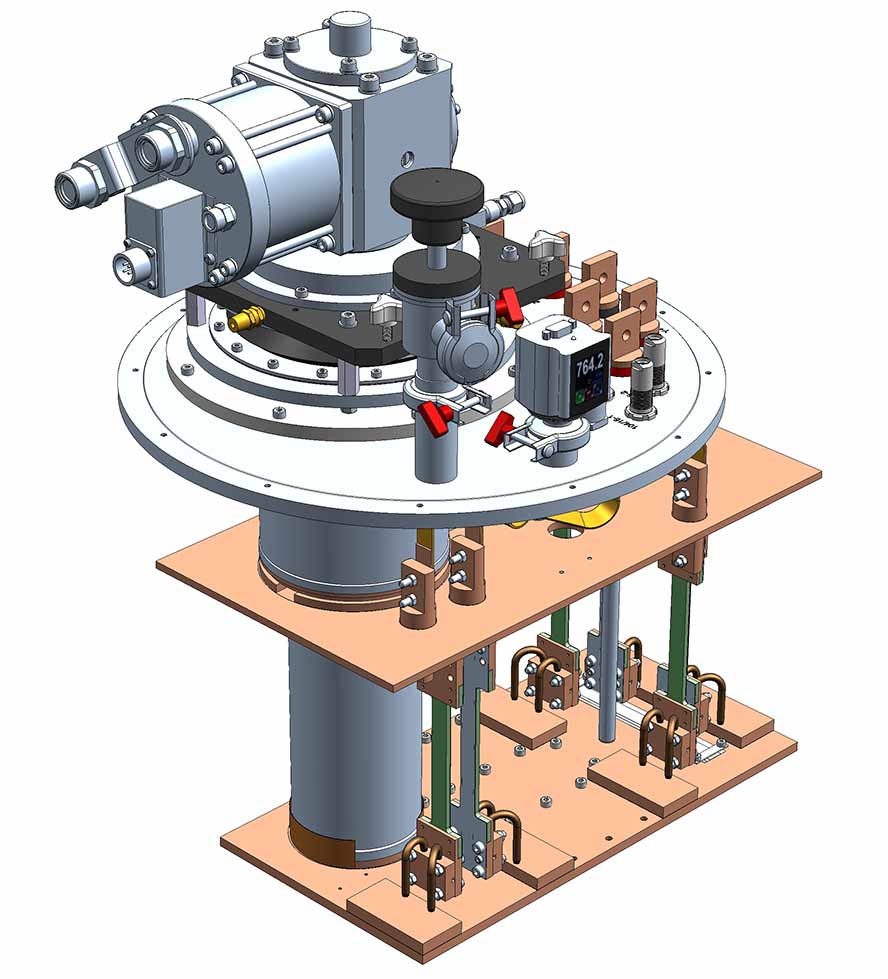

HTS

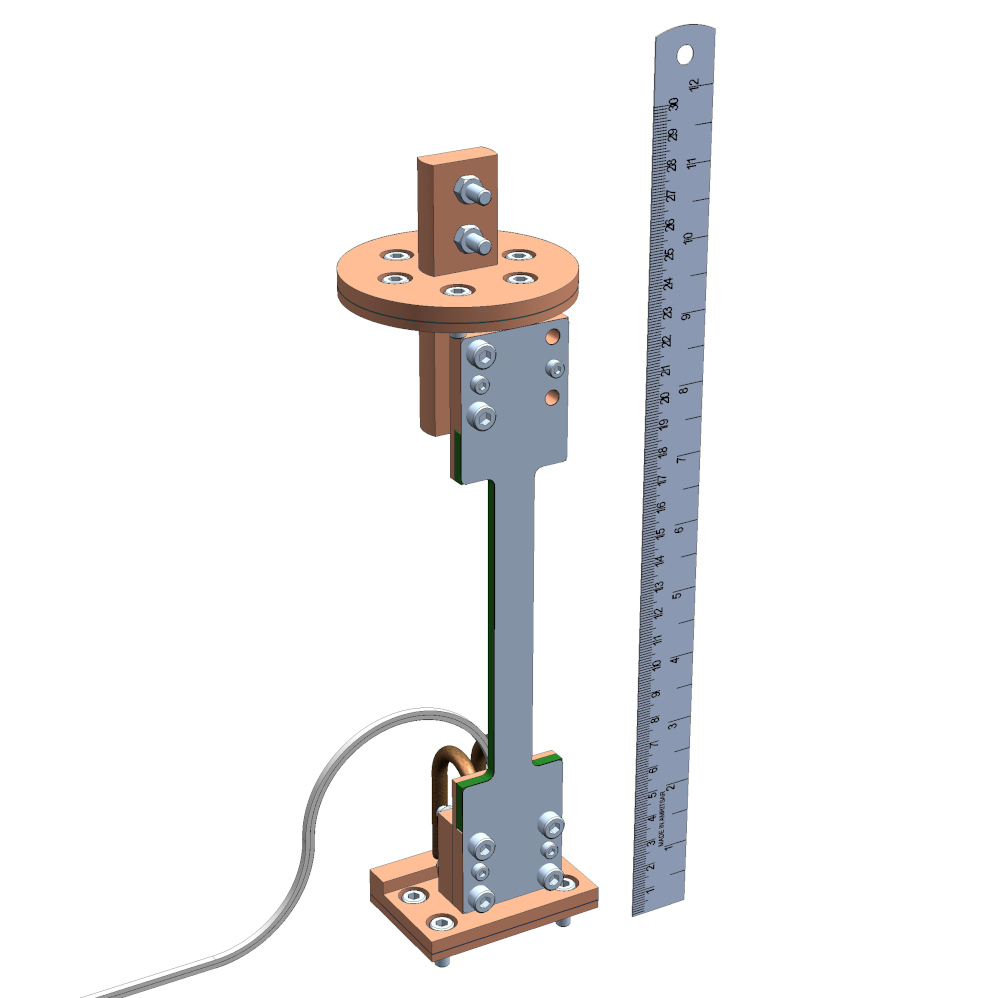

A key technology we consider for all magnet systems is the current lead connection between the power supply and the cold magnet. High-temperature superconductor current leads are generally used to minimise the heat load on a cryogen-free magnet. Scientific Magnetics has a range of standard, and bespoke current leads utilising second-generation HTS conductors, capable of delivering hundreds of Amps to the magnet system with only a few milliwatts of heat load to the 4K stages.

Design Tools

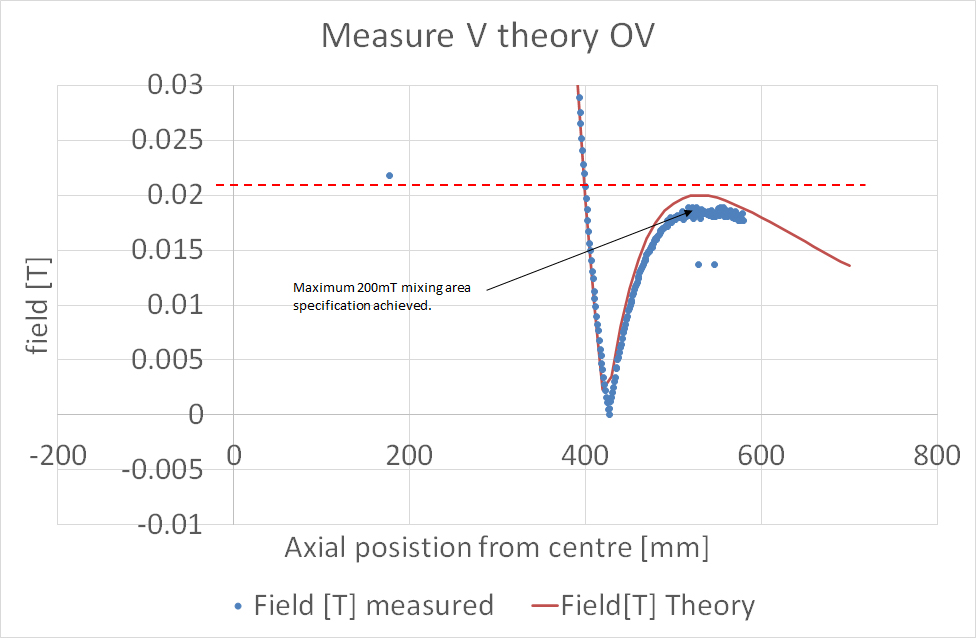

A range of industry-standard tools and bespoke software packages are used by Scientific Magnetics to design and develop our magnet systems.

These include Dassault Systemès Opera Simulation, COMSOL Multiphysics and Siemens Solid Edge. The internally developed software allows us to rapidly prototype magnet designs and analyses quench behaviour.

We regularly analyse linear and non-linear magnetic materials and run static and time-dependent thermal simulations. We offer our professional services on a contract basis where possible.